THE GLYCOL INC.™ ADVANTAGE

Summary:

Glycol, Inc.’s main product offerings are ChillerGlycol™ DF1 and BoilerGlycol™ DF1. Both products are high purity inhibited propylene glycol heat transfer fluids, and were designed with longevity in mind. In addition to providing freeze protection and temperature stability, ChillerGlycol™ DF1 and BoilerGlycol™ DF1 were formulated to protect against corrosion of piping and line components constructed of many varying materials.

Quality Through Guaranteed Purity:

ChillerGlycol™ DF1 and BoilerGlycol™ DF1 boast high purity ratings that are always guaranteed given the fact Glycol, Inc. only offers propylene glycol products with USP/EP/JP/FCC-Certified base glycols. Glycol, Inc.’s PGs also exceed USP monograph including non-detectable MEG and DEG (<0.008%), which is substantially better than any competitor’s product. Many clients come to Glycol, Inc. after our competitors’ products did not work sufficiently. This is typically due to the fact many of our competitors’ products do not utilize USP certified base glycols. Uncertified base glycols typically contain high levels of impurities such as ethylene glycol, diethylene glycol, dioxolanes, and high levels of non-detectable MEG and DEG values, thus shortening the life of the glycol and leading to increased corrosion of their system’s piping and materials. You can rest assured that when investing in glycol from Glycol, Inc., you can always count on a consistent chemical formulation that will provide a reliable, consistent level of performance and protection.

GLYCOL, INC.’S PROPYLENE GLYCOL CERTIFICATIONS & ACCREDITATIONS INSTILLS CONFIDENCE:

Glycol, Inc.’s products only are made from base products in which the highest levels of certifications, regulatory compliance, stringent quality assurance, and good manufacturing practices (GMP) are consistency sustained. Below is a list of certifications and regulatory compliances of Glycol, Inc.’s propylene glycol products:

• Pharmacopoeia Certifications:

• United States Pharmacopoeia (USP) Certified

• European Pharmacopoeia (EP) Certified

• Japanese Pharmacopoeia (JP) Certified

• Other Pharmacopoeia Information:

• All plants USP testing exceeds USP monograph including non-detectable MEG and DEG (<0.008%).

• All plants USP testing exceeds 99.5% assay minimum at an astounding 99.8% minimum tested.

• Meets Brazilian Pharmacopoeia requirements, but not tested for Brazil.

• Other Food Certifications and Approvals:

• Food Chemical Codex (FCC) Compliant.

• FDA approved “Generally Recognized As Safe” of main ingredients, which includes Propylene Glycol (21 CFR 184.1666) and Dipotassium hydrogen phosphate (182.6285).

• USDA listed as chemically acceptable for both defrosting refrigeration coils and for immersion freezing of wrapped meats, poultry, and meat products in food processing plants operated under federal inspection.

• Manufacturing Plant Details:

• Manufacturing plants of base propylene glycol are:

• ISO 9001-2015 Certified

• Kosher Certified

• Most are Halal Certified

• Adherence to IPEC-POG Good Manufacturing Practices (GMP) for Pharmaceutical Excipients.

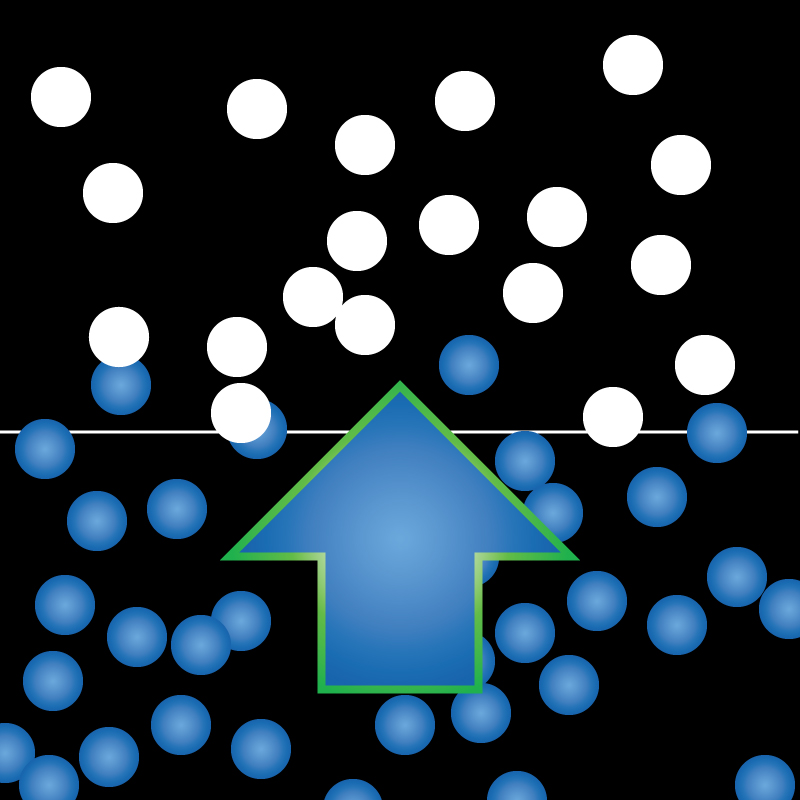

FREEZE PROTECTION:

ChillerGlycol™ DF1 and BoilerGlycol™ DF1 provide superior protection against frozen components and piping in any chilled water or boiler system. When a chiller’s evaporator, pump, or piping is installed in a low fluid temperature or low ambient temperature application, freeze protection becomes critical. If freeze protection is not adequate, all or some of the chiller system could be irreversibly damaged. For instance, when a chiller system’s evaporator freezes, it could expand enough to crack or burst the internal heat transfer plates or tubes causing refrigerant to intermingle with the process fluid. This water to refrigerant contamination can quickly destroy an entire refrigerant circuit including compressors, condensers, metering valves, filter dryers, solenoid valves, and other line components. It is designed to protect insulated piping from freezing in low ambient temperatures down to -50F (-46C).

LOW VAPOR PRESSURE REDUCES EVAPORATION:

ChillerGlycol™ DF1 and BoilerGlycol™ DF1 are considered high boiling point fluids because of its low vapor pressure compared to water at any temperature. This makes ChillerGlycol™ DF1 and BoilerGlycol™ DF1 ideal choices for high temperature applications. Process heating systems and combination chiller/heater systems frequently utilize the product due to this added versatility.

HIGH BOILING POINT:

ChillerGlycol™ DF1 and BoilerGlycol™ DF1 are considered high boiling point fluids because of its low vapor pressure compared to water at any temperature. This makes ChillerGlycol™ DF1 and BoilerGlycol™ DF1 ideal choices for high temperature applications. Process heating systems and combination chiller/heater systems frequently utilize the product due to this added versatility.

ENERGY EFFICIENT PROCESS DELIVERS BIODEGRADABLE PRODUCT:

The high purity base glycol contained in ChillerGlycol™ DF1 and BoilerGlycol™ DF1 is produced from cutting-edge technology which involves a process which converts hydrogen peroxide to propylene oxide (HPPO) through high pressure, high temperature, noncatalytic hydrolysis. After an intricate separation process involving high vacuum distillation, the cleanest form of propylene glycol is produced with a 99.8% or greater assay rating. Conventional process reactions necessary to create propylene glycol produce a large amount of byproduct wastewater. Through technological advancements in HPPO technology (hydrogen peroxide to propylene oxide), Glycol Inc. can proudly state that its propylene glycol products are created from processes which reduce wastewater by 70-80 percent. This HPPO technology also reduces energy usage during the process by 35 percent. HPPO technology was recognized by the Institution of Chemical Engineers’ Innovation and Excellence Award in Core Engineering in 2009, and the United States Presidential Green Chemistry Challenge Award in 2010. Additionally, the propylene glycol contained in ChillerGlycol™ DF1 and BoilerGlycol™ DF1 is biodegradable, and will break down in the environment no matter whether conditions are anaerobic or aerobic, which poses no harmful effect to the environment compared to other HTFs which cannot be broken down.

MINIMAL FLAMMABILITY:

The fluid mechanical properties of ChillerGlycol™ DF1 and BoilerGlycol™DF1 allow the products to drastically enhance lubrication in a loop circulation system. It can increase the life of pumping components such as seals, motorized valves, flow switches, flow meters,and other various loop components which utilize moving parts.

LUBRICATION & FLUIDITY:

ChillerGlycol™ DF1 and BoilerGlycol™DF1 are non-flammable when in solutions up to 80 percent glycol to water due to the fact they have no measurable flash point at those concentrations. With so many other lubricants and oil based fluids being highly flammable, it helps knowing your chiller or boiler system is using a fluid that is completely non-flammable when ran at appropriate concentrations in the system.

TOXICITY:

Glycol Inc.’s propylene glycol products are non-toxic and non-corrosive, therefore it is easy to handle, store, ship, and dispense. The ingredients contained in ChillerGlycol™ DF1 and BoilerGlycol™ DF1 are not considered hazardous under the criteria of the Federal OSHA Hazard Communication Standard 29CFR 1910.1200, nor are they regulated by the Hazardous Materials Transportation Act (HMTA) under the Secretary of the Department of Transportation. Furthermore, the fluid does not require any special HAZMAT chemical placarding for storage purposes. Please view Safety Data Sheets (SDS) for more information.

LEAK DETECTION:

ChillerGlycol™ DF1 and BoilerGlycol™ DF1 are clear (colorless) fluids, and when diluted with water from 20% to 50%, the fluids would be clear (colorless). However, both products can be purchased with a light blue tinted appearance upgrade package to allow simple leak detection in line piping, tanks, or other process equipment. When the blue tinted option is purchased, the fluids maintain a blue hue even when diluted with water from 20% to 50%, which allows easy visibility. For tanker deliveries (over 1,100 gallons), the blue dye package is shipped loose for field mixing with the clear (colorless) standard fluid.

WIDE FUNCTIONAL TEMPERATURE RANGE:

ChillerGlycol™ DF1 and BoilerGlycol™ DF1 can be used in applications ranging from -50F to 250F, which allows the products to be some of most versatile fluids on the market. Solutions in water can provide freeze protection below -60F (-51C), and burst protection below -100F (-73C).

COST IMPACT:

ChillerGlycol™ DF1 and BoilerGlycol™] DF1 are available only through Glycol, Inc’s website, www.glycol.com. As an end user or project manager, this empowers you to purchase the products directly Glycol, Inc with free shipping to the 48 continental United States. This allows your chiller system to utilize the best heat transfer fluid available while avoiding costly markups due to purchasing overpriced competitor products that may not be best suited for your application.

OVERCOMING MARKET VOLATILITY WITH PRICING CONSISTENCY:

The propylene glycol raw materials market is consistently volatile. Any major event, downturn, or natural disaster can affect smaller supply chain manufacturers dramatically causing their pricing to spike at any time. By developing a comprehensive inventory management system and establishing several key industry relationships, Glycol, Inc. is firmly established with access to the largest propylene glycol raw material supply capacity globally. Glycol, Inc. has access to marine, rail, and truck delivery capabilities coming from five impressive global manufacturing facilities producing the largest propylene glycol volume worldwide.

FREE FLUID ANALYSIS CONSULTING:

Glycol, Inc.’s offer free advice to customers regarding fluid system analysis. For larger systems containing over 250 gallons of Glycol, Inc. fluid products, a free analysis is available. For clients with smaller fluid volume systems, Glycol, Inc. can recommend an inexpensive auxiliary testing kit to allow an end-user to perform their own on-site fluid analyses.

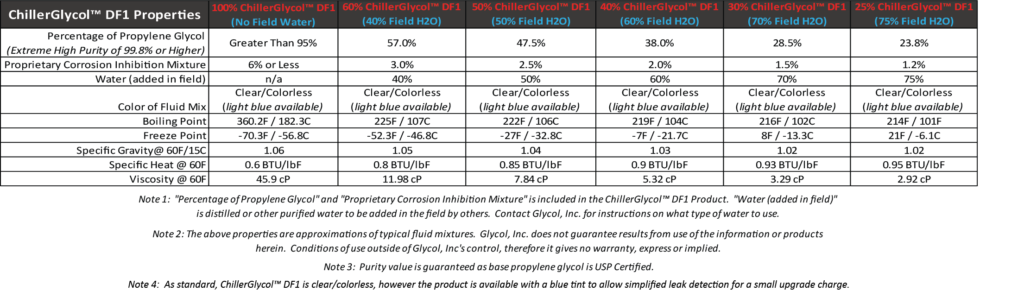

PROPERTIES OF CHILLERGLYCOL™ DF1 AT VARIOUS CONCENTRATIONS:

The fluid mechanical properties of ChillerGlycol™ DF1 and BoilerGlycol™DF1 allow the products to drastically enhance lubrication in a loop circulation system. It can increase the life of pumping components such as seals, motorized valves, flow switches, flow meters,and other various loop components which utilize moving parts

APPLICATION VERSATILITY:

ChillerGlycol™ DF1 and BoilerGlycol™ DF1 are designed to be used in commercial, industrial, or process chiller and boiler systems which require freeze protection, corrosion resistance, lubrication, or increased temperature stability. This could include industrial applications such as cooling a lathe process or laser cooling all the way to brewery jacketed tank cooling. The USP Certified glycol base allows the products to be used with food-grade processes where incidental contact with either food or humans could occur. Running a percentage of ChillerGlycol™ DF1 and BoilerGlycol™ DF1 in your chilled water loop will ensure that you protect your chiller, pumps, piping components, and downstream process equipment investments, increase the longevity of your equipment and piping, and provide an overall extra layer of temperature stability due to its thermodynamic properties.

Here is a list of some typical applications where Glycol, Inc.’s products are utilized:

o Air Preheating

o Airplane Deicing

o Cold Room Dehumidification

o Conveyer Roller Defrosting

o Cooling Liquid Foods

o Fermentation Cooling

o HVAC System Freeze, Corrosion, and Burst Protection

o Ice Bank Cooling

o Immersion Cooling/Freezing

o Packaging Carbonated Beverages

o Process Cooling & Heating

o Refrigeration Coil Defrost

o Warehouse Floor Heating Systems

o Pavement Snow and Ice Melting Systems

o Solar Heating Loops

o Waste Heat Recovery

GLYCOL PRODUCTS

-

Quick View

- BoilerGlycol™ Shop

55 Gallons – BoilerGlycol™ DF1 – 100% USP Grade Inhibited Propylene Glycol

- $2,173.00 – $2,208.00

- Select options This product has multiple variants. The options may be chosen on the product page

-

Quick View

- ChillerGlycol™ Shop

55 Gallons – ChillerGlycol™ DF1 – 100% USP Grade Inhibited Propylene Glycol

- $2,173.50 – $2,208.00

- Select options This product has multiple variants. The options may be chosen on the product page

-

Quick View

- BoilerGlycol™ Shop

275 Gallons – BoilerGlycol™ DF1 – 100% USP Grade Inhibited Propylene Glycol

- $9,108.00 – $9,177.00

- Select options This product has multiple variants. The options may be chosen on the product page

-

Quick View

- ChillerGlycol™ Shop

275 Gallons – ChillerGlycol™ DF1 – 100% USP Grade Inhibited Propylene Glycol

- $9,108.00 – $9,177.00

- Select options This product has multiple variants. The options may be chosen on the product page